3D printing is pushing the envelope and revolutionizing traditional industry. More and more companies are turning to 3D printing for its adaptability and ability to produce "on demand. A true lever of innovation, 3D printing is still in its infancy and is predicted to have a bright future.

What is 3D printing?

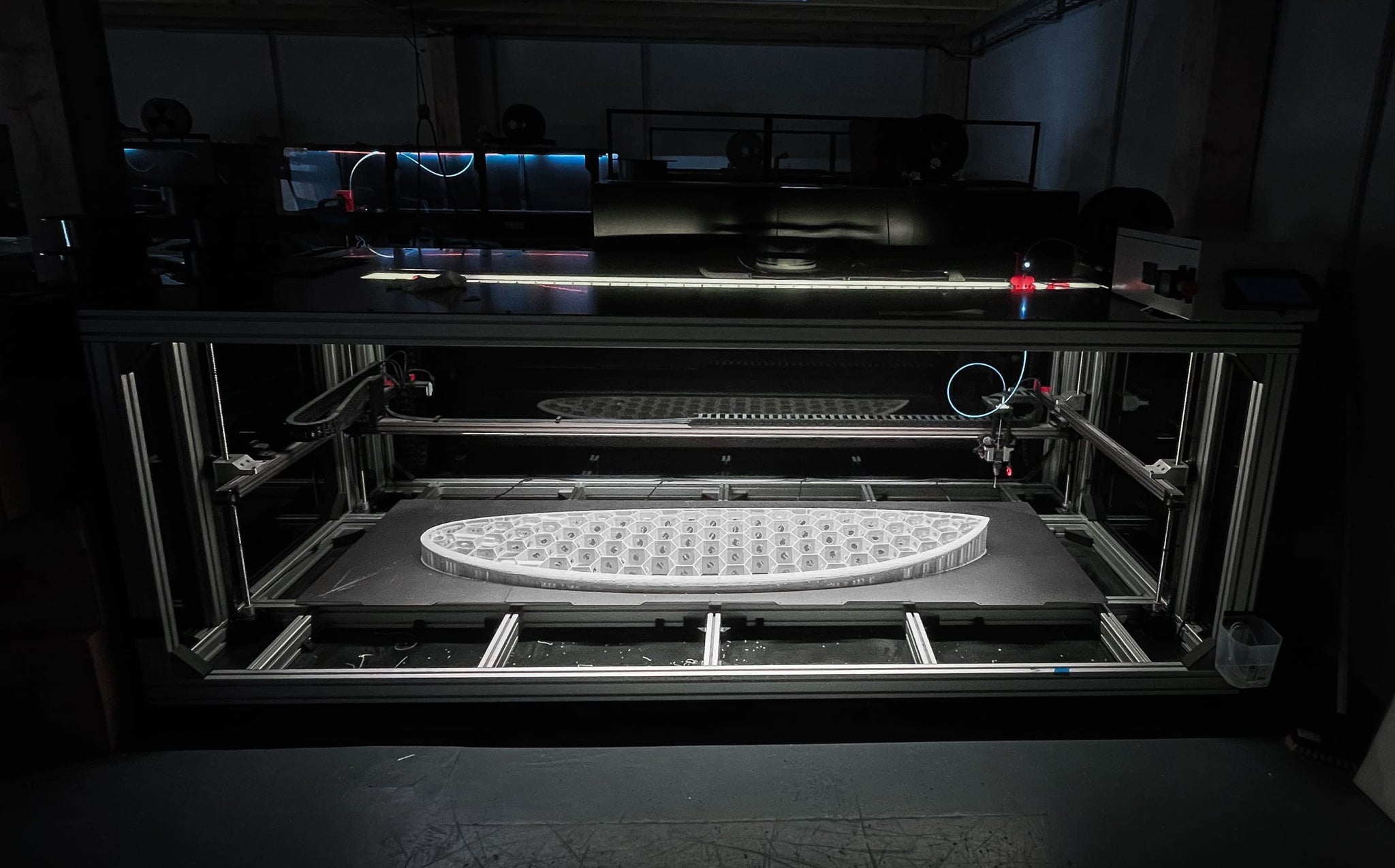

3D printing is a manufacturing process that converts a digital 3D file into a physical part. Whatever the 3D printing technology used, the construction of the object is done layer by layer.

A solution for local manufacturing?

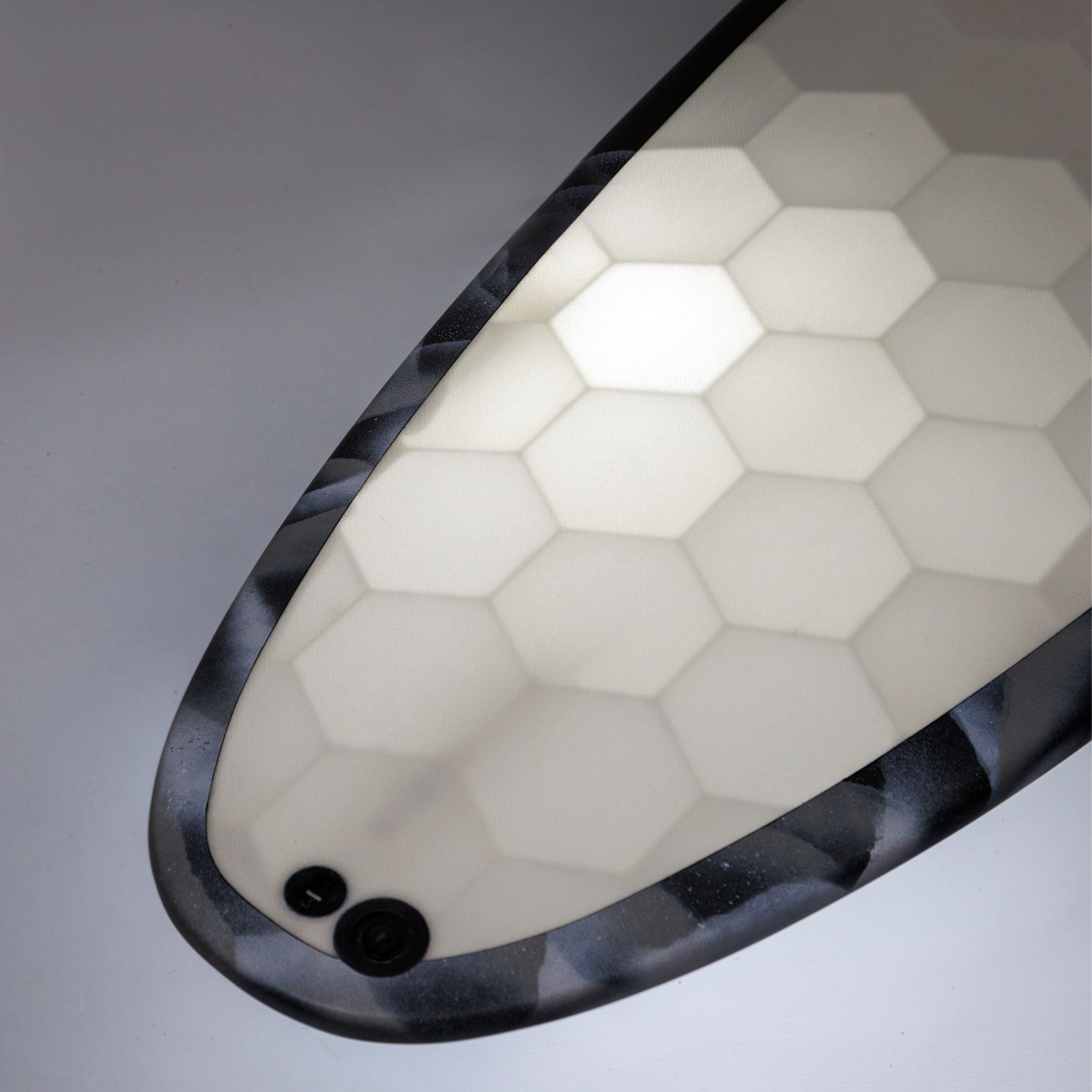

3D printing is characterized by its independent character: its autonomy to produce objects locally following ideas in only a few hours. The freedom of choice of materials, whether biodegradable, bio-sourced, recyclable but also resistant, such as polymers with carbon, flax or glass fiber, through more flexible materials like copper or wood.

This localized autonomy allows to reach a sovereignty and to produce locally while avoiding to place orders at the other end of the world. This technology is a solution to produce in France.

An ecological answer?

3D printing brings an ecological answer and almost infinite possibilities. This technology allows us to produce prototypes very quickly to be very agile in the development of a new product. It is a tool that develops thecircular economy: recycling of thermoplastic materials by grinding them and transforming them into filaments to then reuse them to create new objects. It also allows Makers* to avoid programmed obsolescence by repairing their objects themselves by printing missing or damaged parts.

Why did Wyve choose 3D technology?

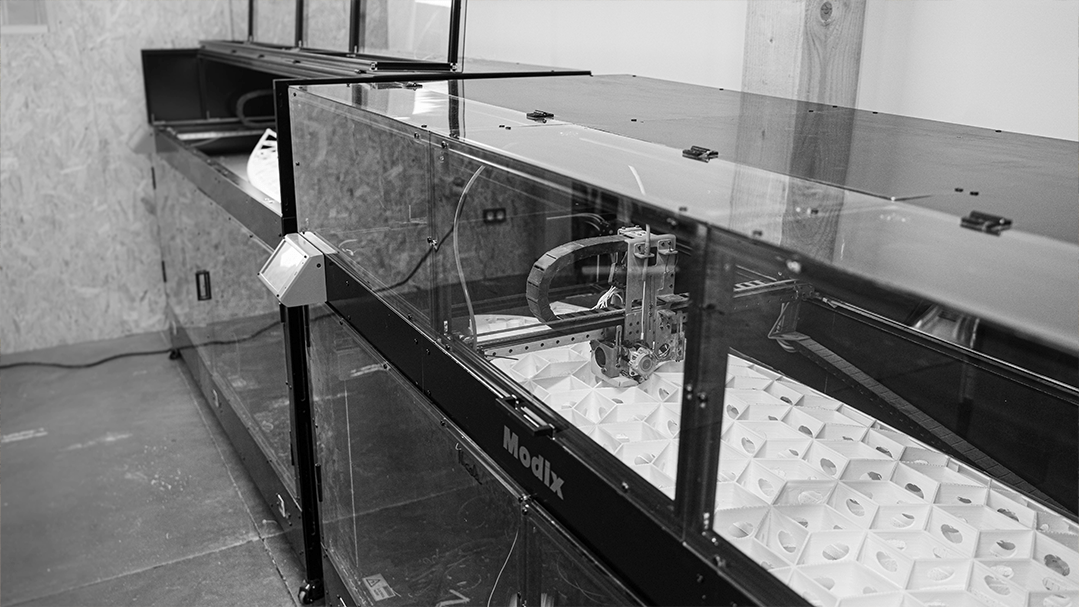

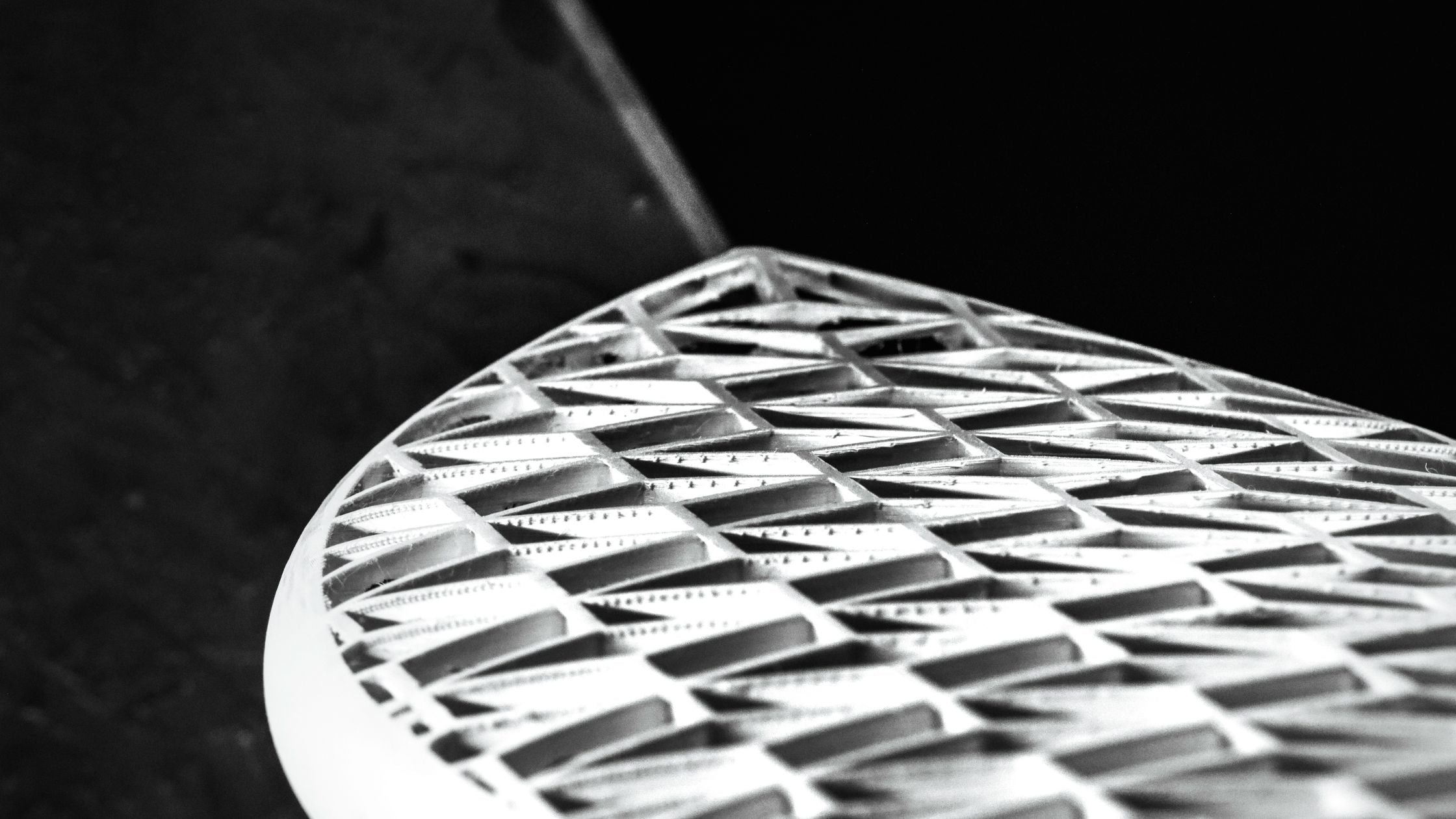

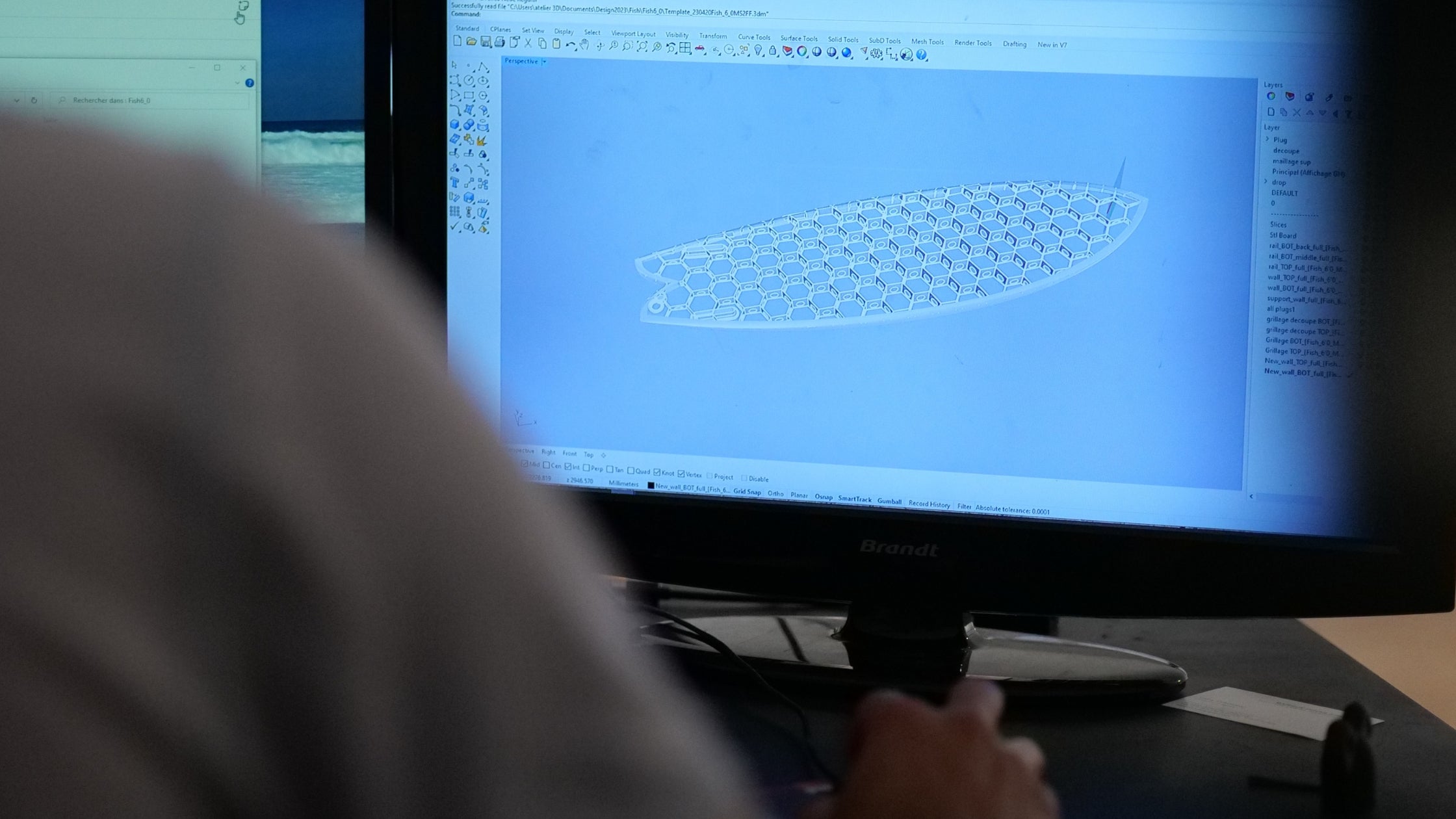

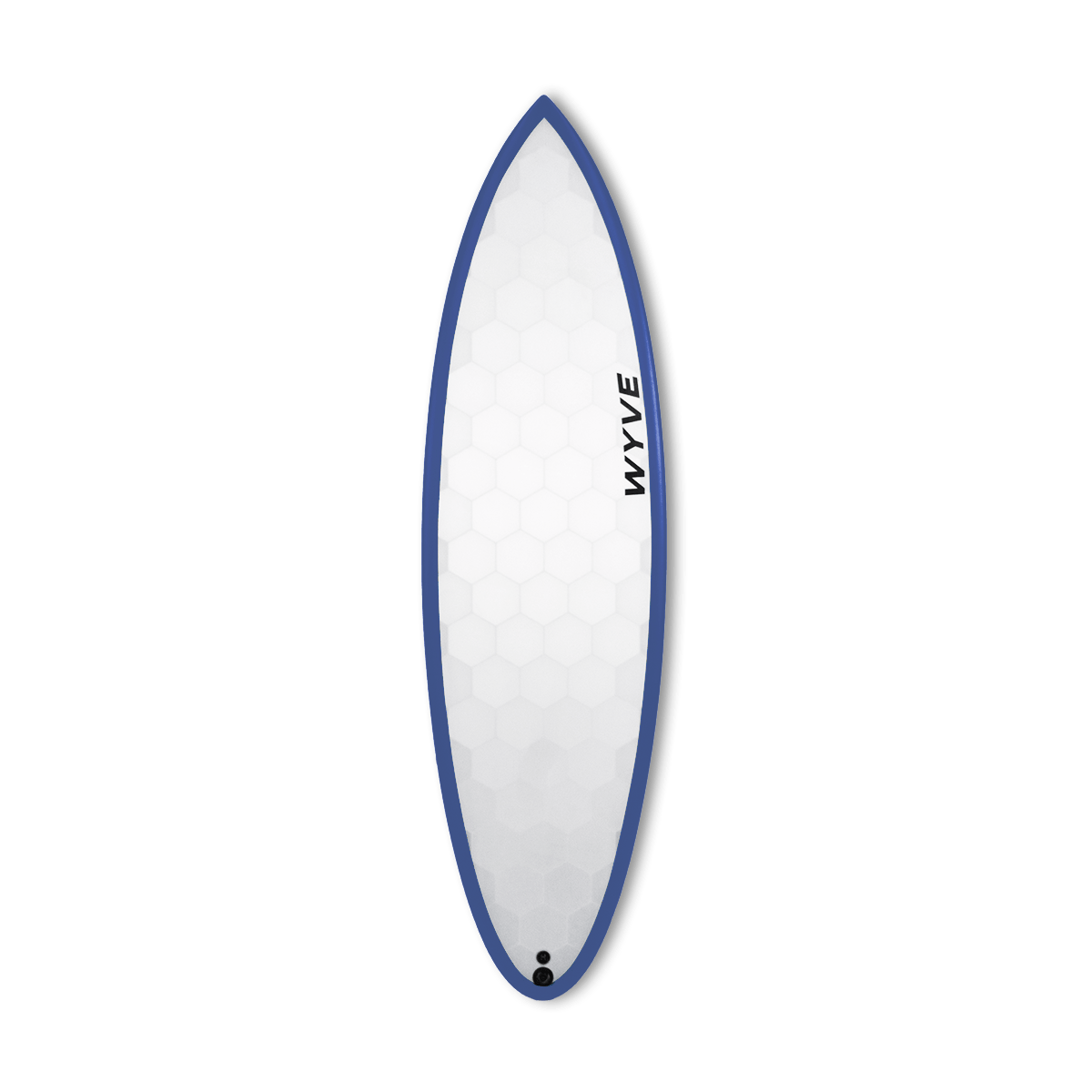

Wyve chose 3D printing to work on performance, eco-design and local manufacturing of surfboards. 3D technology allows us to develop an optimized structure that takes into account different mechanical parameters (speed, control, vibration absorption) depending on the surfer. This manufacturing process is carried out in Anglet in our micro-factory. Internalizing it allows us to manage raw material stocks to gain efficiency and have a tight production flow. Everything is produced on demand and customized, there is no overstocking of finished products.

France is one of the pioneer countries in the field of 3D. Even today, some people still wonder about the interest and use of a 3D printer, just like those who wondered about the impact and use of websites in the 2000s.

When it comes to the future of 3D printing, there's a lot to write about today, and Wyve has chosen to write its chapter.

*Maker = inventive individual who makes objects useful to his daily life via 3D printing